I joined the Peace Corps in 1974 while based in Baltimore.

When I graduated from Stevens Institute of Technology in 1972, I became a pollution control test/service engineer and worked for two years in power plants, cement factories and paper and steel mills throughout the United States and Canada. After six months as a sales engineer I was bored.

At the age of 25 and against the advice of friends, co-workers, and family, I joined the Peace Corps. The agency sent me to Liberia where I worked for the Ministry of Rural Development for one year in Monrovia and then I had the good luck to become their roving field engineer in the northern county of Lofa, near the border with Guinea.

Two years in the Peace Corps “bent” my career path away from what I thought I wanted to be when I was in college; I was no longer interested in machine design, aeronautics, or electric power plant design.

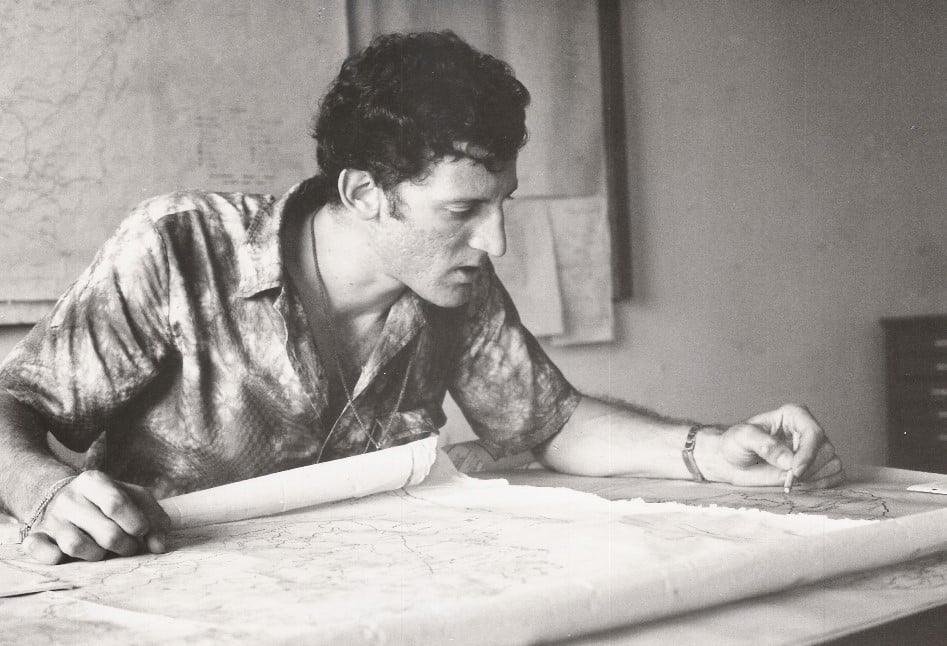

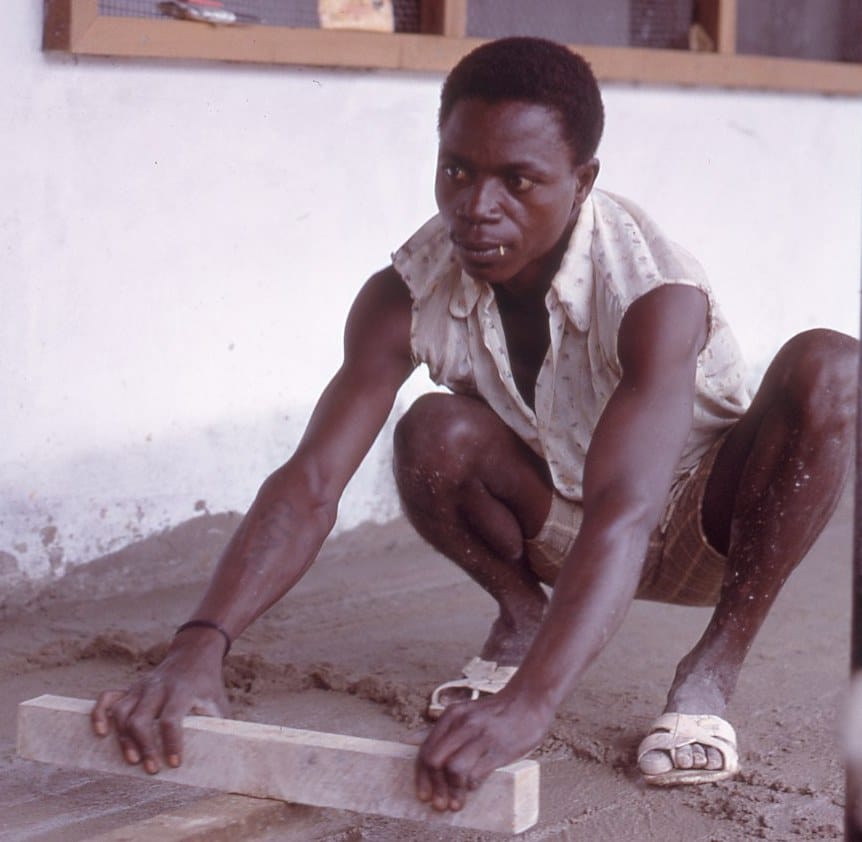

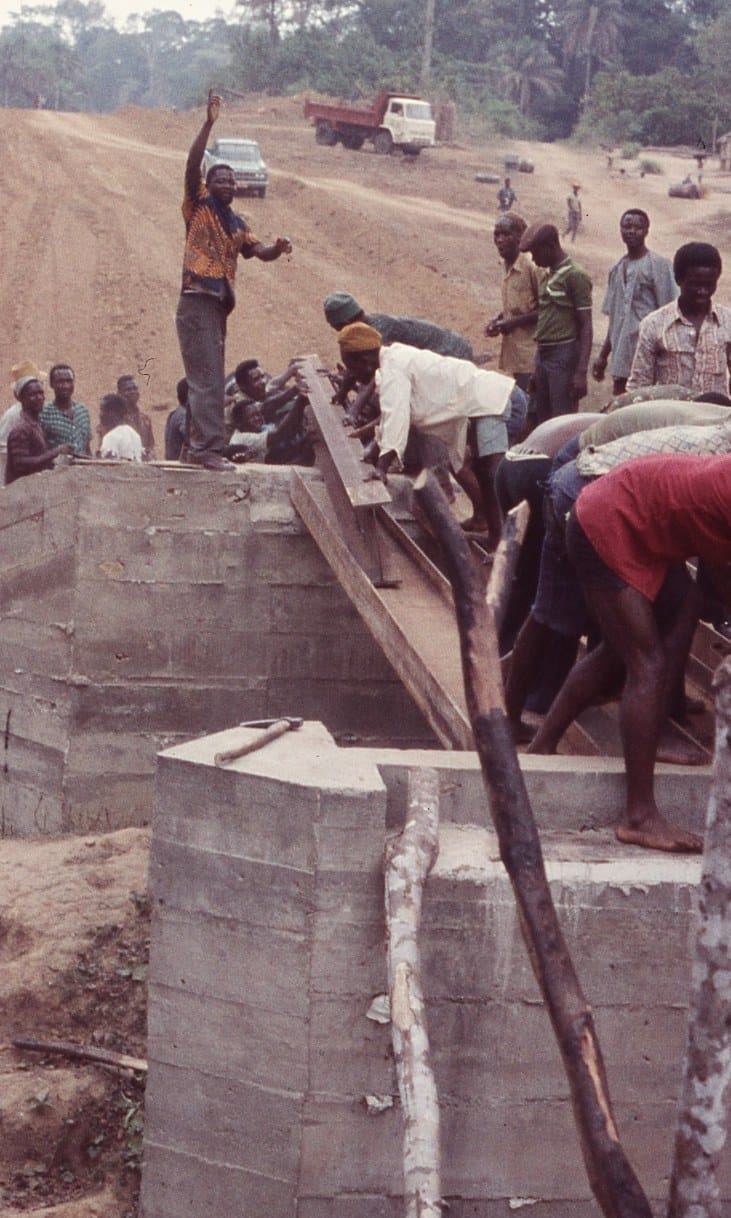

In two years working in Liberia I taught myself how to survey, size drainage culverts for roads, and design reinforced concrete beams and foundations, optimize compressed earth block strength, and designing earth block/reinforced concrete construction for rural public schools, town markets and public health clinics. I supervised the design for a latrine project and designed several larger schools. I submitted budgets to the Ministry and learned with the help of a translator how to negotiate with chiefs in villages.

Moving to Zorzor

As the roving field engineer in the city of Zorzor I drove the poorly maintained dirt roads of Lofa and Bong Counties. I surveyed for new stream crossings for farm-to-market roads—the length, terrain, and number of villages in-between. And I rolled up my sleeves to change the oil and replaced damaged parts on the D-8 Caterpillar the Ministry used for road building. I was delighted to leave the bridge-building to a couple of other Peace Corps civil engineers.

My role included training other Peace Corps volunteers who were making and curing cement earth blocks, laying out building sites, fabricating trusses, and vehicle maintenance. I expedited and coordinated shipments of materials between the Ministry and our volunteers. Wherever I traveled, I stayed with volunteers and solved some of their technical problems: disassembling and fixing a jammed camera mechanism, repairing their school’s only microscope, or building a wood-fired oven so a local home economics class can bake cookies for local fundraising.

In the chip industry

When I ended my Peace Corps tour, I didn’t know a thing about semi-conductor manufacturing but I believed I could design and build manufacturing facilities. I found a great fit at Texas Instruments. Why did they hire me? They were very much a “roll up your sleeves and get the job done” company with factories overseas in developed and developing countries. I think they respected my tenacity and commitment to two years in Liberia in Peace Corps and my previous experience in industrial design and construction.

But now I was back in my mechanical engineering element and again teaching myself what I didn’t know about very complex systems required to manufacturer semi-conductor chips.

When I left Texas Instruments I sought more challenging projects as a facility engineer specializing in semi-conductor/cleanroom factories. I designed and oversaw building one-of-a-kind mechanical systems within factories the size of six football fields that made the microprocessors that are now the “brains” of our modern technological world. I spent 21 years in facility design and construction at Intel’s California headquarters and their Oregon site. For the last 20 years I’ve invented, analyzed, or designed just about everything from air pollution control to waste treatment, and from gas systems to precise environmental controls. Greenhouse gas reduction strategies were my favorite specialty.

I came home having made a small, but profound impact for the indigenous Liberians. The Peace Corps experience did give me an affinity for overseas travel and working in developing countries. My family lived in Ireland for two years and I worked briefly in China, El Salvador, Japan, Israel, Costa Rica, Thailand, and many European countries.

I have never regretted my choice. It helped me define the engineering career I desired. My engineering designs were more minimalist and efficient in materials I used and energy consumed.

I’ve worked in technology spanning between earthen building blocks and products so complex that a couple hundred invisible-to-the-eye dust particles can render a million-dollar product useless.

The author is a professional engineer who has designed semi-conductor factories in Arizona, California, Oregon, Ireland, and Israel.